news

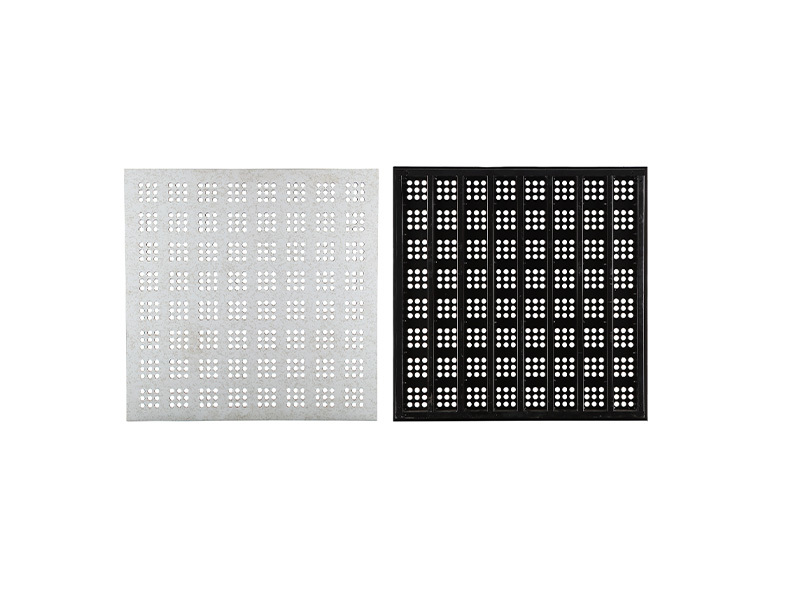

Perforated Panel – Precision Meets Design

2025年08月28日

Perforated panels are a perfect combination of strength, function, and style, widely recognized as one of the most versatile materials in modern architecture, engineering, and design. Manufactured from high-quality metals such as aluminum, galvanized steel, or stainless steel, these panels deliver exceptional durability while offering endless creative possibilities. They are engineered to endure demanding environments without compromising on visual appeal.

The defining feature of a perforated panel lies in its carefully crafted pattern of holes, slots, or decorative shapes. Each design can be customized according to acoustic, structural, or aesthetic requirements, allowing the panel to serve both practical and artistic purposes. In everyday use, perforated panels provide effective solutions for noise reduction, ventilation, filtration, safety barriers, and decorative enhancements. Their geometric precision ensures consistent performance while adding a unique surface texture that transforms plain walls or ceilings into eye-catching focal points.

Architects often employ perforated panels in façades, ceilings, partitions, and sunshades. By filtering sunlight and airflow, they help regulate temperature, create natural ventilation, and maintain privacy while allowing buildings to remain open and inviting. The play of light and shadow through the perforations adds depth and character, enabling designers to shape distinctive atmospheres and highlight architectural identity.

In industrial contexts, perforated panels excel as protective screens, machinery guards, and separation systems. Their high strength-to-weight ratio provides safety without unnecessary heaviness, while resistance to rust and corrosion ensures longevity even under harsh working conditions. Furthermore, their recyclability and compatibility with eco-friendly coatings make them a sustainable material choice aligned with modern environmental standards.

Another advantage is their flexibility in fabrication. Perforated panels can be cut, bent, or curved into complex forms, offering adaptability for both small-scale interiors and large-scale construction projects. Surface treatments such as powder coating, painting, or anodizing expand the range of colors and finishes, giving designers full freedom to integrate them seamlessly into contemporary or traditional settings.

Ultimately, perforated panels are far more than sheets of metal with holes. They are dynamic design tools that merge performance with artistry. From reducing noise in transportation hubs, to optimizing airflow in factories, or creating dramatic building façades, they perform with reliability and elegance. Their combination of durability, flexibility, and timeless beauty makes them a material of choice for architects, engineers, and designers around the world.

Related news

Contact us

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Email address

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Company address

Hengshanqiao Town, Wujin District, Changzhou City, Jiangsu Province

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.