Aluminum Floor – Lightweight, Durable, and Versatile Solution

2025年08月22日

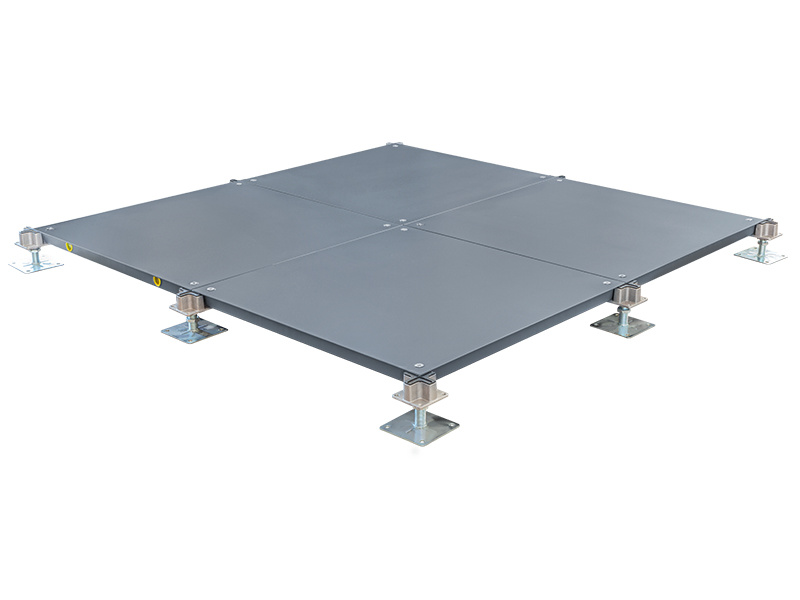

An aluminum floor is a modern flooring solution made from high-strength aluminum alloys, known for their lightweight structure, durability, corrosion resistance, and aesthetic appeal. Compared with traditional materials such as steel, wood, or concrete, aluminum floors provide a perfect balance of strength and weight, making them ideal for applications in construction, transportation, industrial facilities, and architectural decoration.

Key Features:

Lightweight and Strong – Aluminum has a high strength-to-weight ratio, reducing overall structural load while maintaining exceptional load-bearing capacity.

Corrosion Resistance – The natural oxide layer and optional anodizing treatment provide long-term protection against rust and chemical damage.

Slip Resistance – Aluminum flooring can be designed with checker plates, ribbed patterns, or perforated surfaces to improve safety in industrial or outdoor settings.

Aesthetic Design – Polished, brushed, or powder-coated finishes give aluminum floors a modern and stylish appearance.

Easy Installation and Maintenance – Lightweight panels are easy to cut, transport, and install, while cleaning requires minimal effort.

Recyclable Material – Aluminum can be recycled repeatedly without loss of performance, supporting eco-friendly construction.

Common Types of Aluminum Flooring:

Aluminum Checker Plate (Diamond Plate): Popular for truck beds, stairs, walkways, and factory floors due to its anti-slip surface.

Extruded Aluminum Panels: Provide structural strength and are commonly used in modular buildings and industrial platforms.

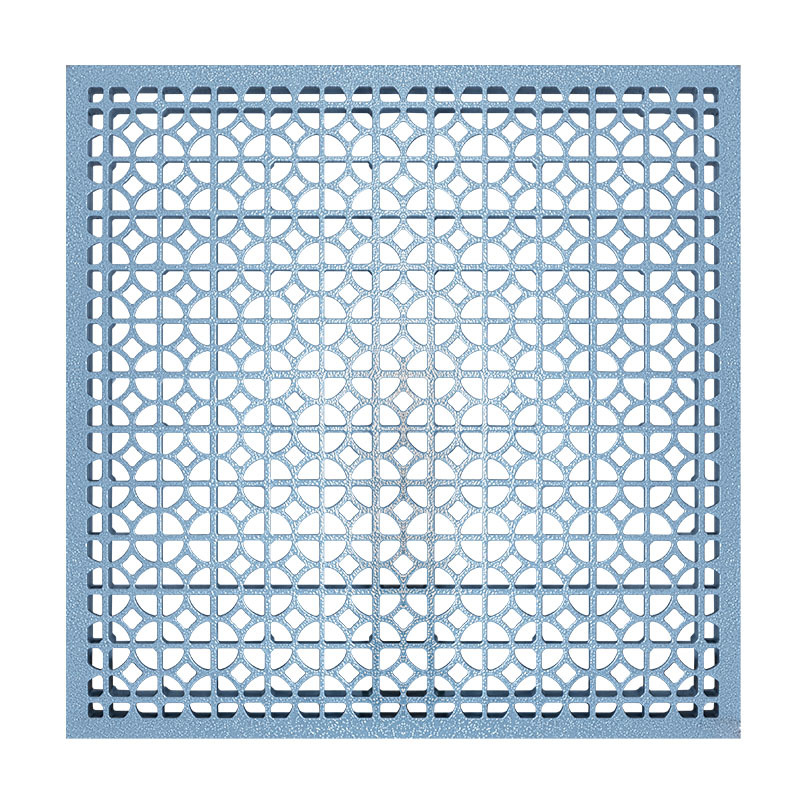

Aluminum Grid/Perforated Floors: Allow airflow and drainage, ideal for factories, chemical plants, and outdoor decking.

Decorative Aluminum Flooring: Used in interior design, exhibition halls, and public spaces for a modern aesthetic.

Applications:

Construction Industry – Used in flooring for commercial buildings, elevators, pedestrian bridges, stair treads, and scaffolding platforms.

Transportation – Lightweight flooring in trucks, trailers, buses, ships, and trains helps reduce fuel consumption and improve efficiency.

Industrial Facilities – Factory floors, oil and gas platforms, chemical plants, and cleanrooms where safety and durability are critical.

Residential and Decorative Uses – Kitchens, garages, and modern interiors requiring stylish, durable, and easy-to-clean flooring.

Advantages over Other Materials:

Compared with steel, aluminum floors are lighter and corrosion-resistant without requiring heavy maintenance.

Compared with wood, they are stronger, fire-resistant, and long-lasting.

Compared with concrete, they are more flexible, quicker to install, and recyclable.

Trends and Future Development:

With the rise of lightweight construction, sustainable materials, and modular building systems, aluminum flooring is gaining wider popularity. Manufacturers are developing multi-layer composite aluminum floors, combining insulation, soundproofing, and anti-slip properties. Integration with digital fabrication and CNC machining allows for precise customization of patterns and finishes. The global push for green building and recyclable materials will further expand the use of aluminum flooring in construction, transportation, and residential projects.

Conclusion:

Aluminum flooring is a lightweight, durable, corrosion-resistant, and recyclable flooring solution. Its versatility makes it an excellent choice for industrial, commercial, transportation, and residential applications. As sustainability and lightweight design become more important, aluminum floors will continue to play a vital role in modern architecture and engineering.