Durable Innovation: Comprehensive Overview of Aluminum Floor Applications and Advantages

2025年08月19日

Aluminum floor is becoming increasingly popular across a wide range of industries due to its exceptional combination of lightweight properties, high durability, corrosion resistance and modern aesthetic appeal. As a structural and decorative solution, aluminum floor offers a practical alternative to traditional flooring materials such as wood, concrete, or steel, especially in applications where weight reduction and excellent mechanical performance are required. In industrial and commercial environments, aluminum floor is frequently installed in factories, warehouses, transportation vehicles, marine vessels and aircraft, where it helps to enhance operational efficiency and long-term cost savings. Compared with other materials, aluminum floor is easier to transport and install due to its lighter weight, enabling faster project completion and a reduction in labor costs. In addition, aluminum’s natural oxide layer provides superior resistance to oxidation and moisture, making it particularly suitable for harsh environments such as coastal areas or chemical processing facilities. The long service life of aluminum floor reduces maintenance requirements and minimizes downtime, which is a critical factor for any business seeking to maximize productivity.

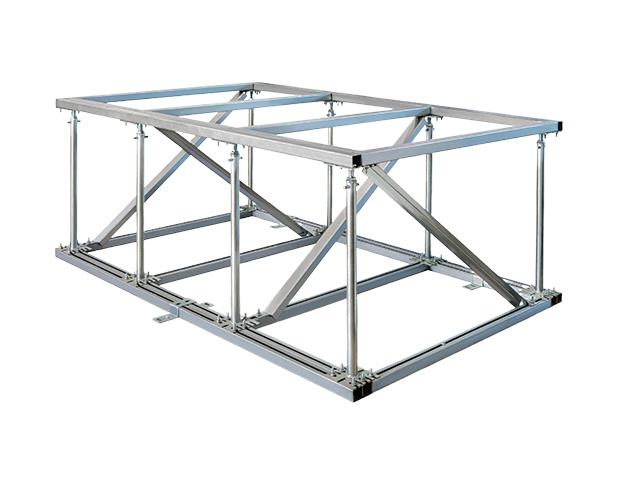

From a structural standpoint, aluminum floor can be manufactured using various extrusion and casting techniques, resulting in a wide variety of profiles, patterns and designs. For example, anti-slip diamond plate or ribbed patterns are commonly used to increase surface friction and improve safety in areas with heavy foot traffic. These specialized profiles are particularly valuable in automotive workshops, loading docks and transportation vehicles, where slip resistance is an essential safety requirement. Aluminum floor also has excellent load-bearing capacity, allowing it to support heavy machinery, pallets and vehicle traffic without deformation. In modern architectural projects, aluminum floor is often used as an interior or exterior design element thanks to its sleek and contemporary appearance. It can be anodized, powder-coated or brushed in a variety of finishes and colors, providing architects and designers with a versatile material that complements both minimalist and industrial styles.

Environmental sustainability is another critical advantage of aluminum floor. Aluminum is a fully recyclable material, and recycled aluminum retains the same mechanical properties as primary aluminum. This makes aluminum floor an ideal option for environmentally-conscious projects and companies striving to achieve green building certifications. During the production process, modern extrusion and casting technologies allow manufacturers to reduce energy consumption and minimize material waste. Moreover, because aluminum floor is lighter than many traditional materials, transportation and logistics-related emissions are also reduced. In the residential sector, aluminum floor is gaining popularity in modular homes, outdoor terraces and rooftop decks. Its superior weather resistance and low thermal expansion rate ensure long-term dimensional stability even in extreme climates. Homeowners appreciate the fact that aluminum floor is easy to clean and maintain, offering a hygienic surface that does not absorb liquids or odors. For renovation and retrofitting projects, aluminum floor panels can often be installed over existing structural bases, significantly reducing renovation time and minimizing disruption to occupied spaces.

In the transportation sector, aluminum floor panels are widely used in buses, trucks, railcars and ships. Their light weight contributes to reduced fuel consumption and increased payload capacities, making them an efficient choice for fleet operators. The high strength-to-weight ratio of aluminum floor ensures a safe and stable platform for passengers and cargo, while its corrosion resistance ensures that the floor maintains its integrity even in highly demanding environments. In the aerospace industry, aluminum floor panels are used in aircraft cabins and cargo holds where every kilogram of weight savings is critical. Maintenance crews also benefit from the ease of cleaning and rapid module replacement capabilities of aluminum floor systems. Modern aluminum alloy compositions, optimized through controlled heat treatment and alloying, further enhance mechanical performance, impact resistance and overall service life.